Revmaster’s Breakthrough R-2300 Engine Offers More Horsepower, Lower Cruise RPM at the incredible low price of $11,700.00

Revmaster’s Breakthrough R-2300 Engine Offers More Horsepower, Lower Cruise RPM at the incredible low price of $11,700.00

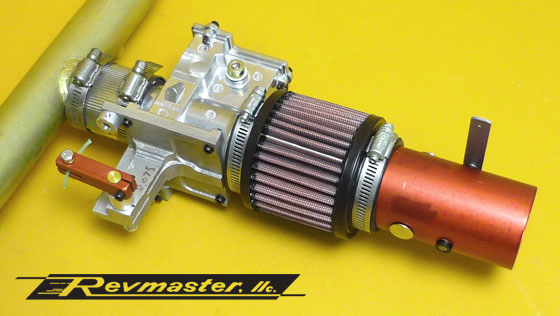

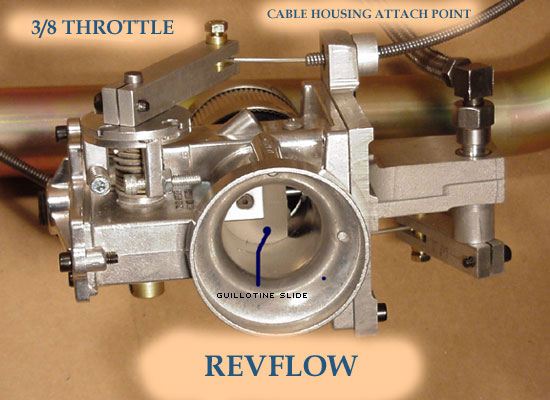

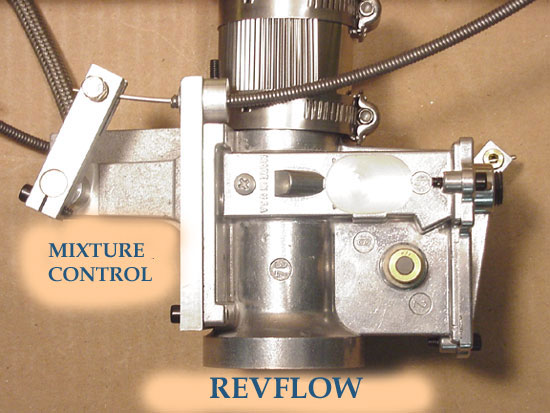

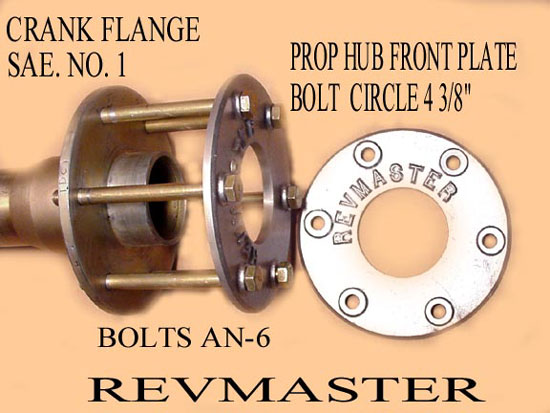

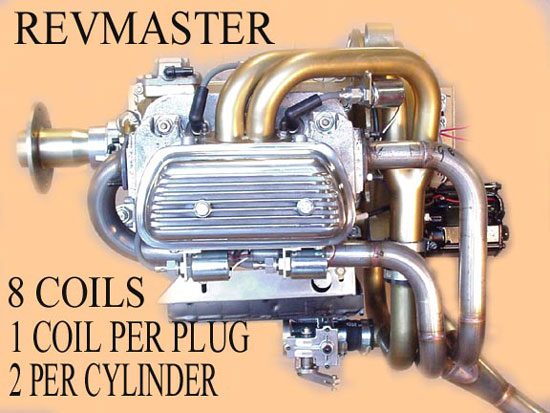

Revmaster Aviation has finished development of its latest upgraded engine, and the results are in: more horsepower at any usable rpm. The new Revmaster R-2300 (2331cc, 142.2 cu.in.) engine maintains Revmaster’s famous proprietary systems and parts, including its RM-049 heads that feature large fins and a hemispherical combustion chamber; and it maintains the earlier R-2200’s engine’s top horsepower (82) at 2950rpm continuous. (Takeoff power is rated at 85, at 3350rpm.) The additional power ultimately comes from a bore of 94mm plus lengthening of the R-2200’s connecting rods, plus increasing the stroke from 78 to 84mm, but that is oversimplifying things. “We have put a lot of energy into this redesign,” says Joe Horvath, President and founder of Revmaster. “On paper it looks like just a few minor modifications, but we’re really closer to a complete rework of the internals: crank specification, rods, pistons, and cylinders are all new.” The longer stroke results in more displacement and longer connecting rods yield better vibration and power characteristics; the lower cruise rpm allows the use of longer propellers – and the higher peak horsepower can be felt in shorter takeoffs and steeper climbs. Strength and reliability are ensured by Revmaster’s 4-main-bearing crankshaft that runs on a huge 60mm center main bearing and is forged from 4340 steel, with nitrided journals. Thrust is handled by the 55mm #3 bearing at the propeller end of the crank. Fully utilizing its robust #4 main bearing, the Revmaster crank has built in oil-controlled propeller capability, a feature unique in this horsepower range; non-wood props are usable with these engines. The direct-drive R-2300 retains Revmaster’s famous dual CDI ignition with 8-coil spark to 8 spark plugs, dual 20-amp alternators, oil cooler, and its proprietary Rev-Flo carburetor, while introducing the longer cylinders that do not require spacers. The automotive-based bearings, valves, valve springs, and piston rings (among others) make rebuilds easy and inexpensive, even as the Revmaster-engineered components have heavy-duty longevity built in. First deliveries have already begun; full production is underway. Pricing for a complete, test-run Revmaster R-2300, complete with geared starter, dual ignition and twin alternators. FOB Hesperia, California (92345).

R-2300 SPECIFICATIONS HP Rating:

85 @ 3200 Continuous HP: 80 @ 3000

Fuel minimum octane: Aviation grade 91/98 – 100LL

Conforming to ASTM D910 Oil: multi-grade 20/50

Bore: 94mm Stroke: 84mm 4 main bearings

Displacement: 2331 cc Firing order: 1 – 4 – 3 – 2

Compression ratio: 8:1

Spark plugs: 12 X 3/4 reach DCPR7E

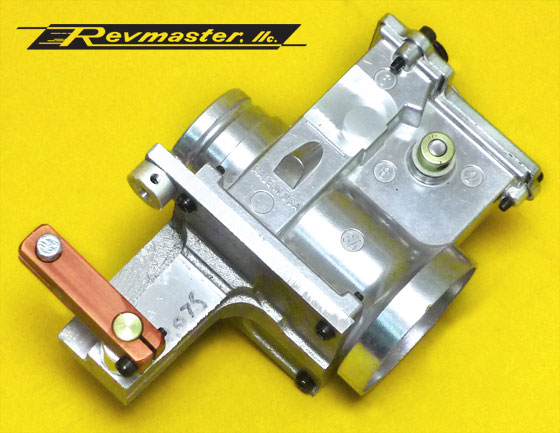

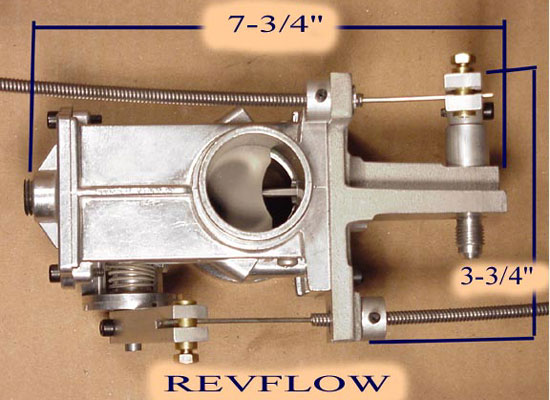

Carburetion: RevFlow 36mm

Ignition: Quad CDI 8 coils

Timing: BTDC 25 degrees

Dual alternator: 20 amp each

Battery: 12V min. 20 amp

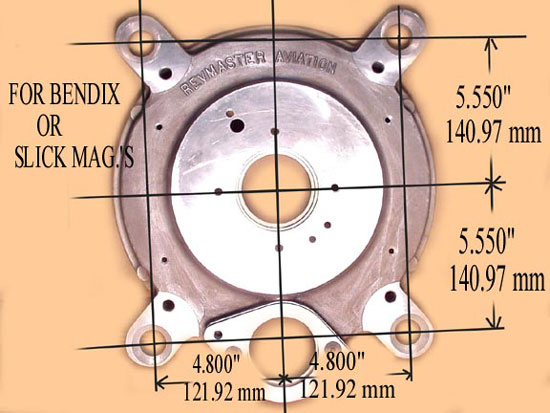

Crank flange: SAE #1 4-3/8″ bolt circle

Dry weight: 170 lbs.

OPERATING LIMITS Max rpm: 4200 Cruise rpm: 3000 +/- 200

Idle rpm: 900 +/- 50

Oil temp min: 130 degrees F

Oil temp max: 220 degrees F (measured at sump)

Oil pressure min: 10 lbs/1000 rpm

Oil pressure max: 80 psi

CHT cruise: 350 – 375 degrees F

CHT climb: 450 degrees F

EGT full rich: 1250 degrees F

EGT max; 1400 degrees F

PRICING Completely assembled and test run before ship…………………………$11,700.00

Including E4340 forged four main bearing aviation crankshaft, starter, alternator system, dual CDI ignition, oil cooler, oil filter, large capacity oil pump, RevFlow carburetor.

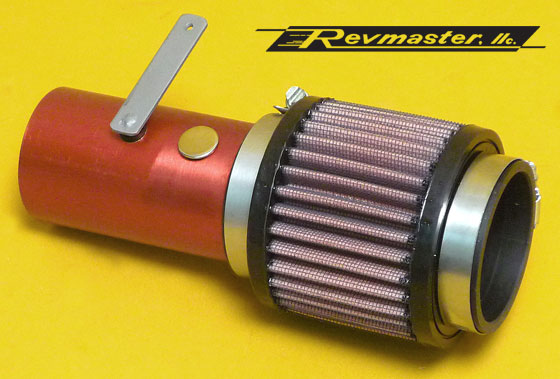

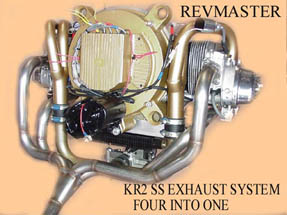

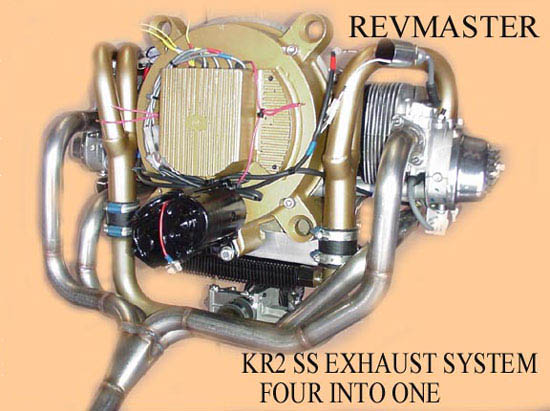

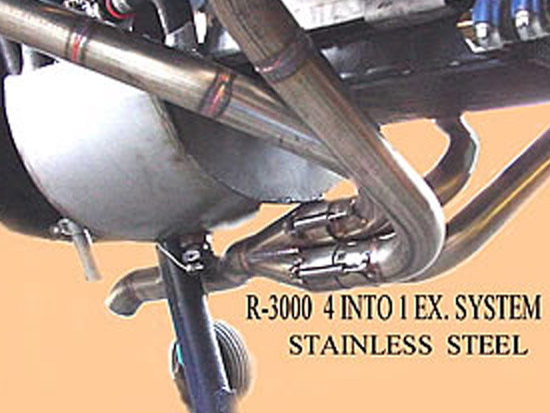

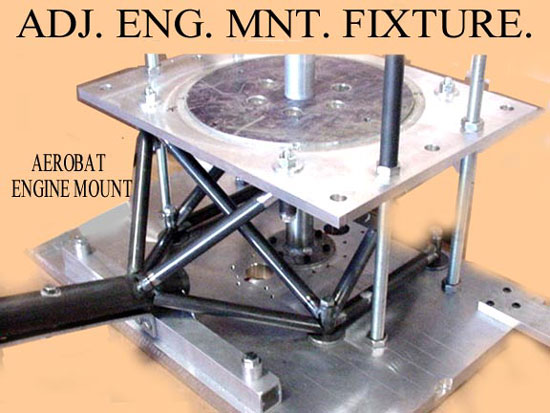

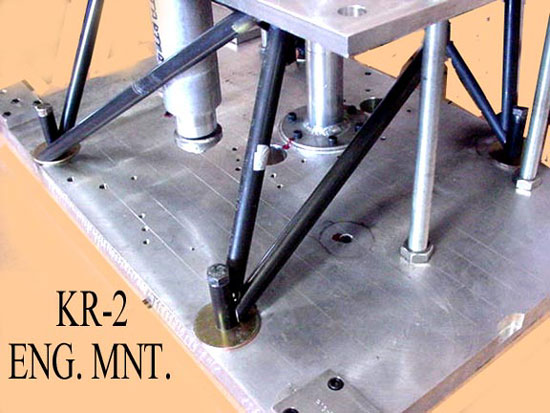

OPTIONAL ACCESSORIES ARE AVAILABLE Exhaust system, engine mount, engine mount hardware, prop crush plate, alternate air source/ram air filter assembly. SALES POLICY Deposit of $3,000.00 is required with engine order. A minimum of 10% of deposit is forfeited upon order cancellation for any reason.

To order: Please call 760-244-3074, or

CLICK HERE to download our printable order form (Adobe PDF).